垂直造型机

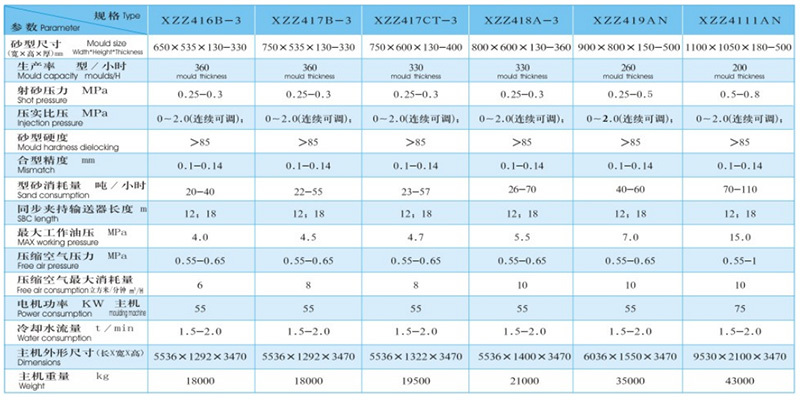

一.造型线主要特点Moulding line feaures 生产率为360型/小时,达到先进水平。 Productivity of 360 models/hour, reaching advanced levels 人工下芯时生产率仍可达到260型/小时 The productivity can still reach 260 types/hour during manual core cutting PLC/触摸屏人机界面操控。 PLC / HMI touch screen control. PLC网络接口,可提供远程快速诊断服务。 PLC network interface can provide remote diagnostic services quickly. 故障自动报警显示及排查,工艺参数存储及自动调整。 Fault alarm display and troubleshooting. process parameters can be stored and automatically adjusted. 吸附式进口型腔底板,耐磨损易更换。 The bottom wear plate is Imported high hardness panel, it improved accuracy,extended life, low cost and easy to replace. 电气、液压、密封元件全部进口,确保运行稳定可靠。 All of the electical, hydraullc, seal components are imported to ensure stable andreliable. 正压板底板为气垫结构,耐磨损、寿命长、合型精度高。 At the bottom of the squeeze plate, we use alr-cushion to ensure the accuracy andprolong life. 具有可靠的合型力控制系统确保砂型不脱开,不挤碎。 With rellable locking force control system to ensure the sand is not torn oft, andnot burst. 无接触式位移传感器确保准确无误。 Using the imported non-contact magnetic position senso, it's rllable, high accuracy,fault less and long life. 主机带有自动防护门,AMC、SBC 带有防护栏网。 The machine has automatic protection door, and the AMC, SBC has ani-fence. 规格多、更经济、便于选择。 Specifications, more economical, convenient options. 二.造型线主要构成 Major components of the moulding line XZZ416/417/418垂直无箱射压造型线由垂直无箱射压造型机、平移式下芯机、同步夹持输送机、皮带冷却输送机.振动落砂机(或滚落砂机) . 加芯机和电控系统组成。 The XZZ416/417/418 vertical fiaskless molding line is composed of a vertical flaskless molding machine,a translational type core setter, a synchronous clamping conveyor, a belt ooling conveyor, a vibratoryshake-out machine (or olling shake-out machine), an adding core machine and an electric contol system. 垂直无箱射压造型机采用射砂、压实的造型原理实现射砂成型.同时可完成起模、合型、推型等动作。 The vertical flaskless molding machine adopts the casting principle of sand election and mould squeezing to achieve the shoot sand molding. At the same time, it is also used to complete the action such as drawing,mold assembling and mold pushing out. 三、主要规格和技术参数Main seificatinis and technical pameters

关键词:

所属分类:

产品描述

一.造型线主要特点Moulding line feaures

生产率为360型/小时,达到先进水平。

Productivity of 360 models/hour, reaching advanced levels

人工下芯时生产率仍可达到260型/小时

The productivity can still reach 260 types/hour during manual core cutting

PLC/触摸屏人机界面操控。

PLC / HMI touch screen control.

PLC网络接口,可提供远程快速诊断服务。

PLC network interface can provide remote diagnostic services quickly.

故障自动报警显示及排查,工艺参数存储及自动调整。

Fault alarm display and troubleshooting. process parameters can be stored and

automatically adjusted.

吸附式进口型腔底板,耐磨损易更换。

The bottom wear plate is Imported high hardness panel, it improved accuracy,extended life, low cost and easy to replace.

电气、液压、密封元件全部进口,确保运行稳定可靠。

All of the electical, hydraullc, seal components are imported to ensure stable andreliable.

正压板底板为气垫结构,耐磨损、寿命长、合型精度高。

At the bottom of the squeeze plate, we use alr-cushion to ensure the accuracy andprolong life.

具有可靠的合型力控制系统确保砂型不脱开,不挤碎。

With rellable locking force control system to ensure the sand is not torn oft, andnot burst.

无接触式位移传感器确保准确无误。

Using the imported non-contact magnetic position senso, it's rllable, high accuracy,fault less and long life.

主机带有自动防护门,AMC、SBC 带有防护栏网。

The machine has automatic protection door, and the AMC, SBC has ani-fence.

规格多、更经济、便于选择。

Specifications, more economical, convenient options.

二.造型线主要构成 Major components of the moulding line

XZZ416/417/418垂直无箱射压造型线由垂直无箱射压造型机、平移式下芯机、同步夹持输送机、皮带冷却输送机.振动落砂机(或滚落砂机) . 加芯机和电控系统组成。

The XZZ416/417/418 vertical fiaskless molding line is composed of a vertical flaskless molding machine,a translational type core setter, a synchronous clamping conveyor, a belt ooling conveyor, a vibratoryshake-out machine (or olling shake-out machine), an adding core machine and an electric contol system.

垂直无箱射压造型机采用射砂、压实的造型原理实现射砂成型.同时可完成起模、合型、推型等动作。

The vertical flaskless molding machine adopts the casting principle of sand election and mould squeezing to achieve the shoot sand molding. At the same time, it is also used to complete the action such as drawing,mold assembling and mold pushing out.

三、主要规格和技术参数Main seificatinis and technical pameters

相关产品

免费获取产品报价

我们的工作人员将会在24小时之内(工作日)联系您,如果需要其他服务,欢迎拨打服务热线:0312-7813689